s

s

Activities:

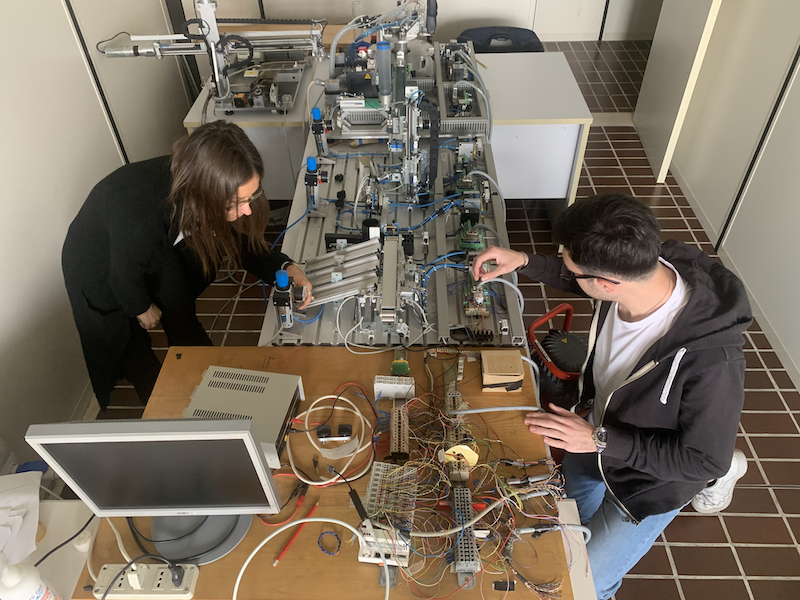

The laboratory stems from the need to provide students with modern tools for the study of production systems, industrial automation systems, production supervision and management systems. The possibility offered by the creation of such a laboratory to verify, by simulation tools analysis and control, the methodologies learned constitutes a significant contribution in the educational program.

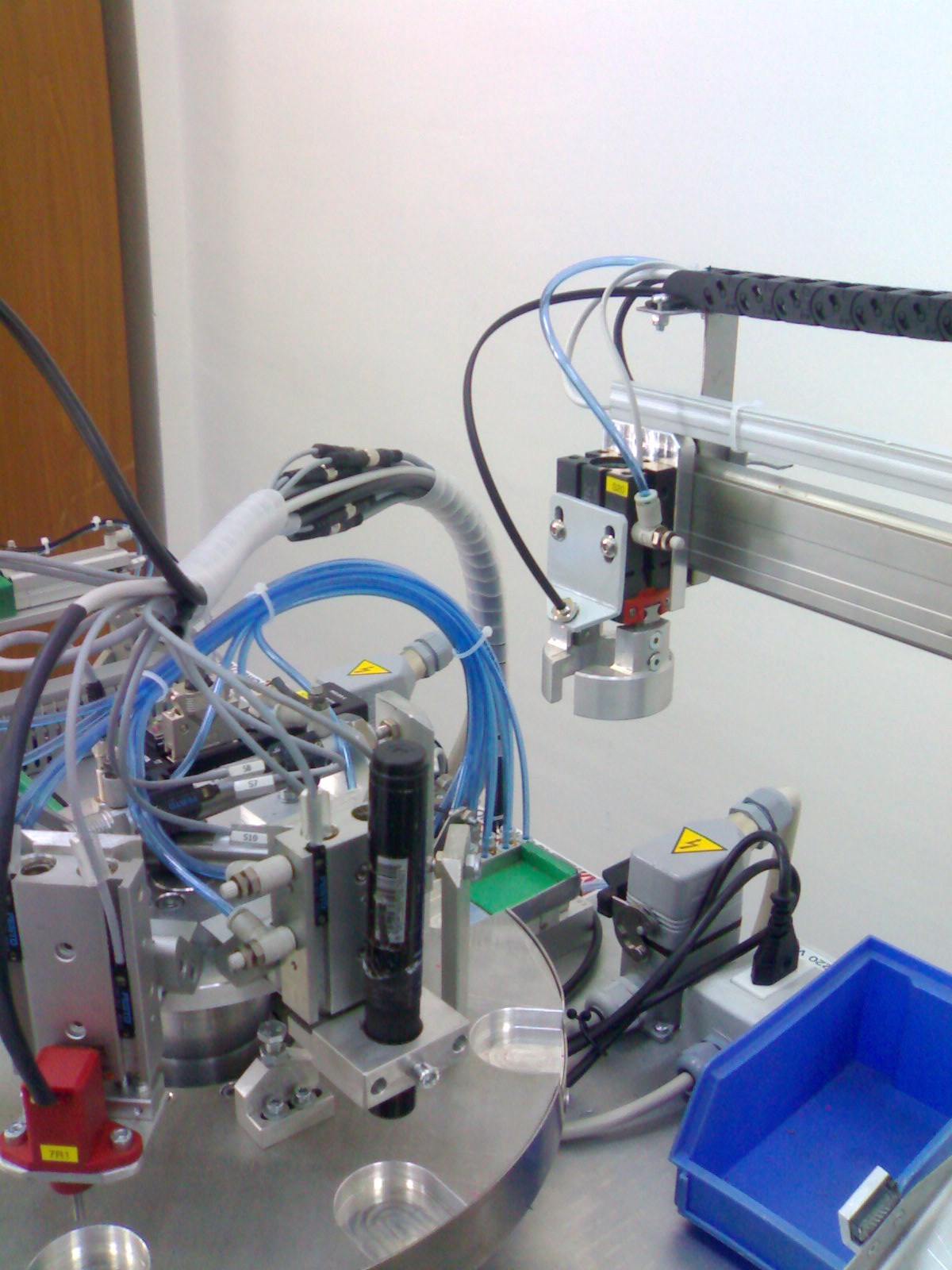

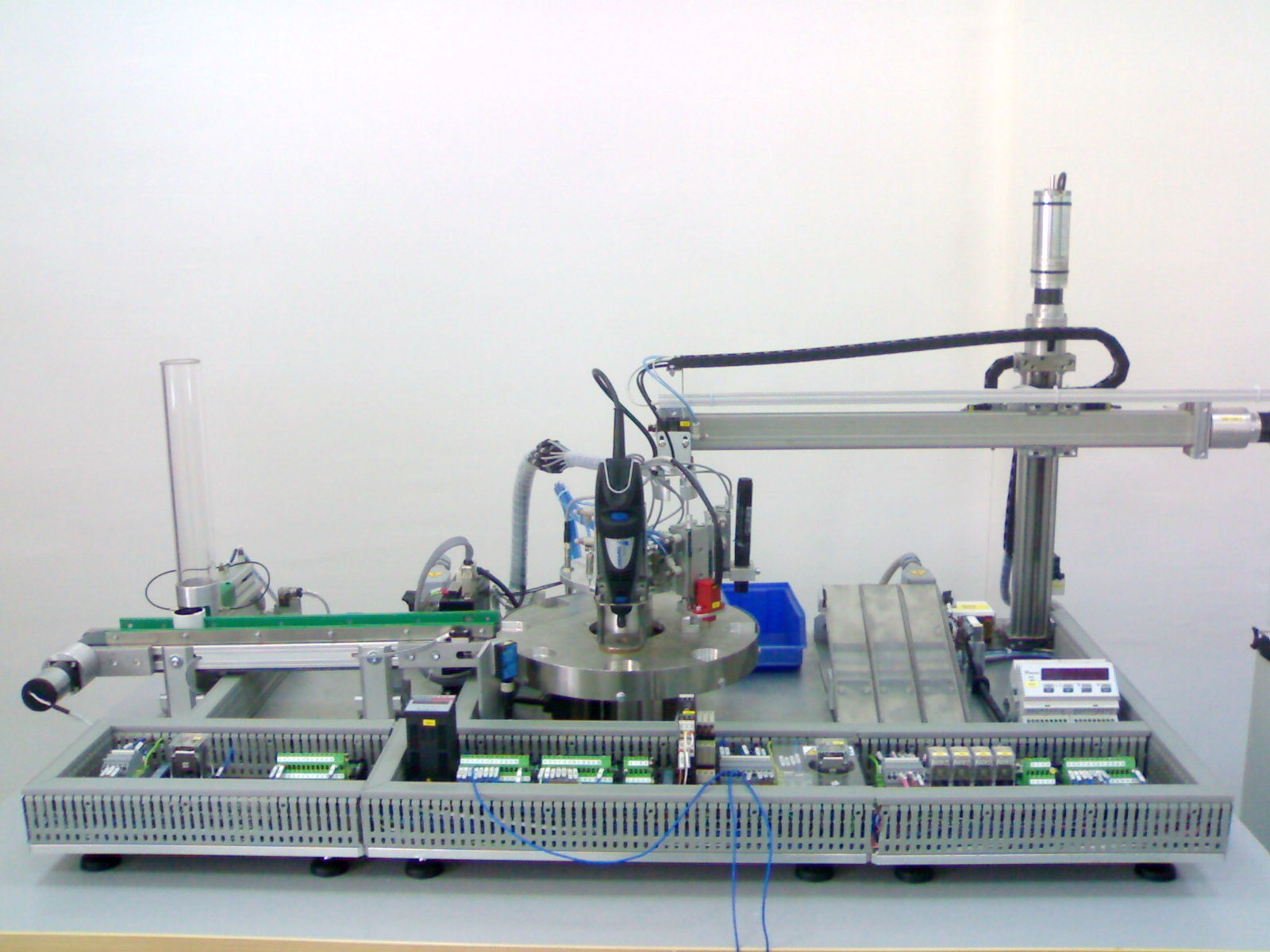

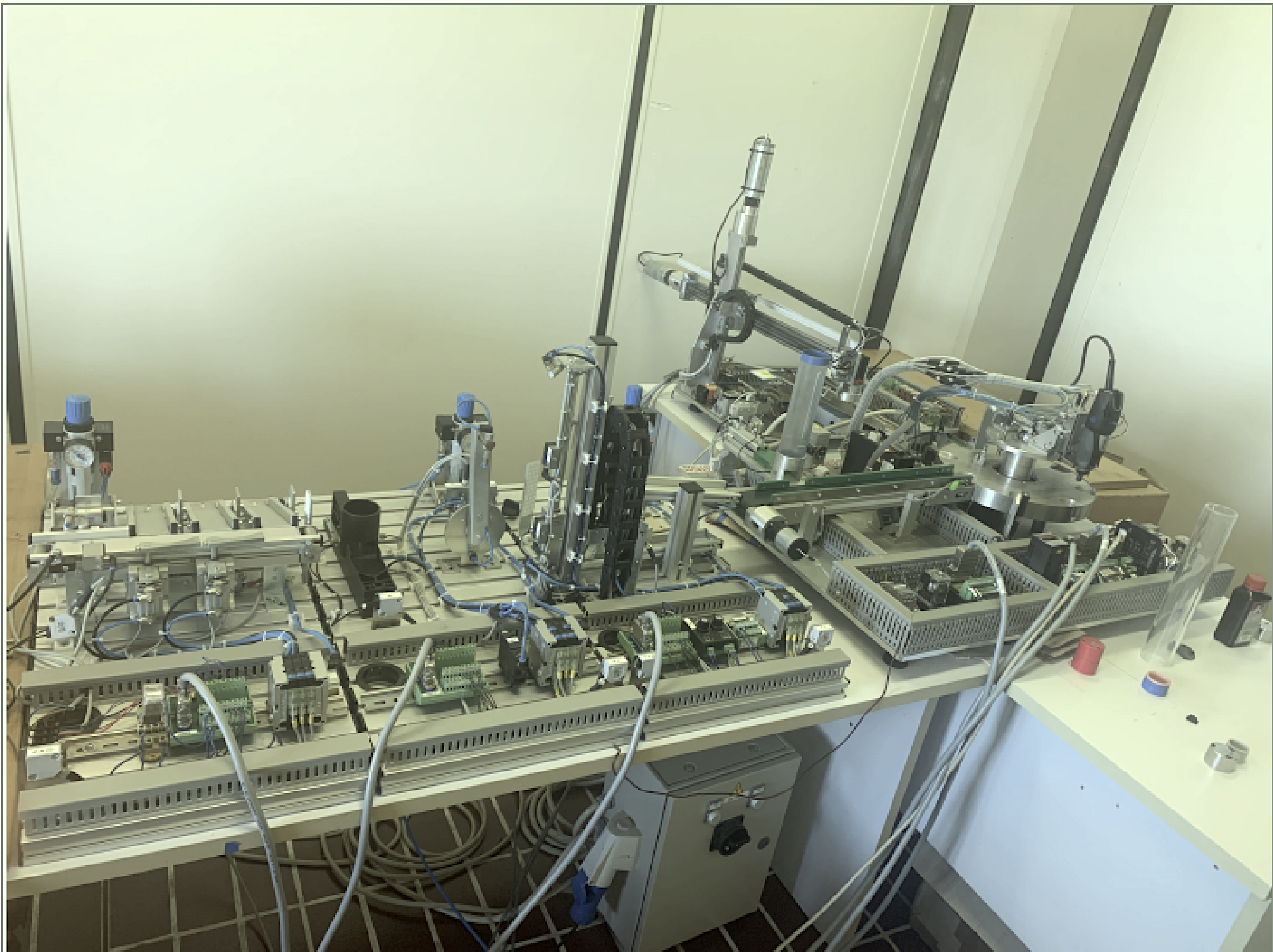

The availability of both simulation software and hardware models, of a flexible small-scale system, consisting of the interconnection of several stations carrying out different automated processes according to different layouts, gives the possibility to analyze the performance of a plant. The LISA group studies and develops complex interconnected systems in the field of automation and control engineering and applied mathematics.

Research and development issues are located in the contexts of energy transition and Industry 4.0: modeling and simulation of discrete event systems, continuous processes, data analysis; development of control, advanced control, predictive control, optimization, scheduling, fault diagnosis, monitoring and predictive maintenance algorithms for industrial/non-industrial processes; project management and project maintenance.

Examples of recent application areas: steel and cement industry, water distribution networks, HVAC plants, refrigeration/freezer plants, hydroelectric plants, district heating plants, smart cities, oil & gas, manufacturing plants, marine and underwater environment, food production sector. The developed solutions can be implemented as needed on different devices and platforms such as PLC and SCADA. The strong industrial value of the activities carried out contributes to the strengthening of the link between the academic and manufacturing worlds by fostering the insertion of graduates into the world of work.